No products in the cart.

Portfolio English

Wood Furniture Maker Should Give Well Finishing, Why?

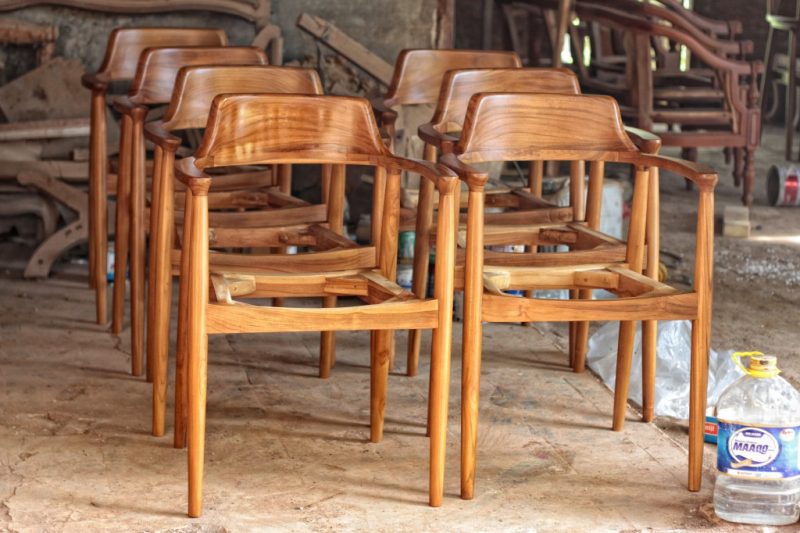

Wood furniture maker has to give finishing touch in the last stage in the manufacturing process. It must be done to put protection in furniture product and also add an aesthetic values.

Wood Furniture Maker’s Purpose of Finishing

Even though solid wood is best material for making furniture but it still need the protection as furniture product surface can be damaged when dealing with particular condition. For example, if you live in very cold country like in Europe which has four seasons. Therefore, surface of furniture requires protection.

Furthermore, the purpose of finishing is to provide color on furniture. There are different tastes of every person. Some people like natural color and the others interest to artificial colors. Therefore, there are many choices in finishing process.

Wood Furniture Maker and The Process of Finishing

The essence of finishing is to give final touch in the process of furniture manufacturing. The finishing process includes smoothing on surface and giving color.

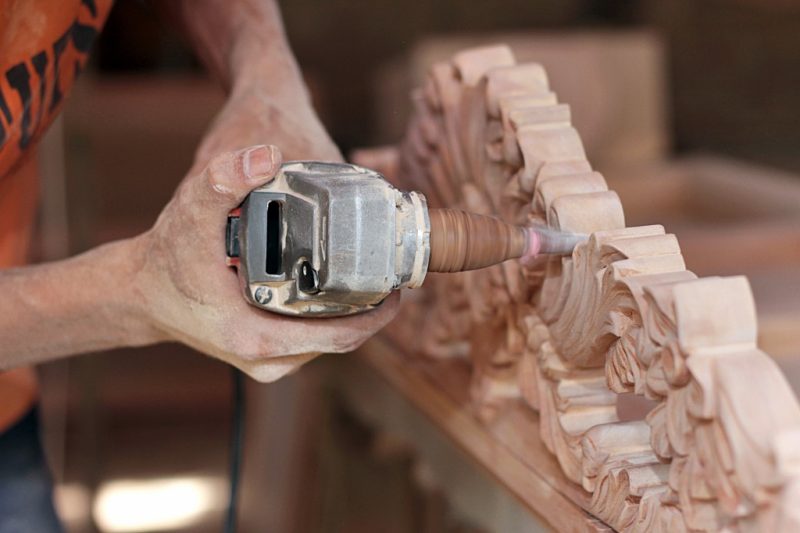

To get the level of fineness on that surface, the tool that is widely used is sandpaper. Some furniture product smoothed after every part is assembled, and some of them smoothed before assembling.

The finishing should be done thorough on the surface to get maximum result. The smoothing in each part can be done manually by rubbing the sandpaper. But for furniture that have carved part and narrow corner that are difficult to reach by hand, it need to use a special tool.

After Wood Furniture Maker Do Finishing

Once again, finishing process has two purposes. First, it is as protection and second is to make the furniture look more beautiful.

Therefore, furniture product that have got the finishing touch will look more elegant and sturdy.

There are some choice in finishing. Some people like a classical nuance, some of them love modern look, and some interest minimalist.